We know what it takes to succeed.

Successful additive manufacturing (3d printing) requires expertise, experience and equipment.

Expertise

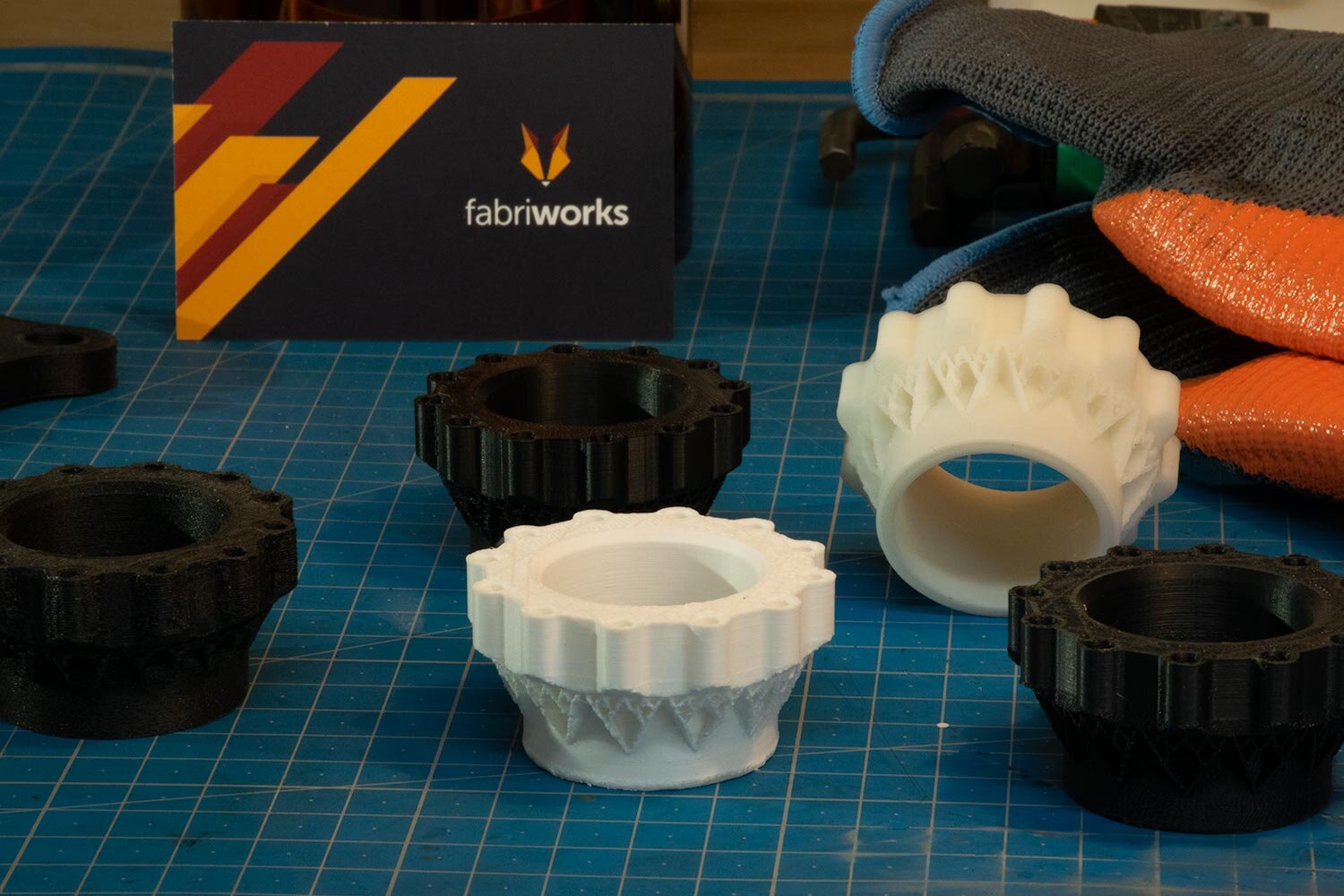

At Fabriworks we have extensive knowledge of thermoplastic polymers and how to best process them. Our industrial printers are ‘open-material’ so we can select the best and most suitable filament for any project.

We work closely with our trusted suppliers and their technical departments to perfect all handling, printing and post-processing operations to ensure top quality results.

Experience

Fabriworks puts its years of hard-earned experience in best-practice materials handling and processing at your disposal.

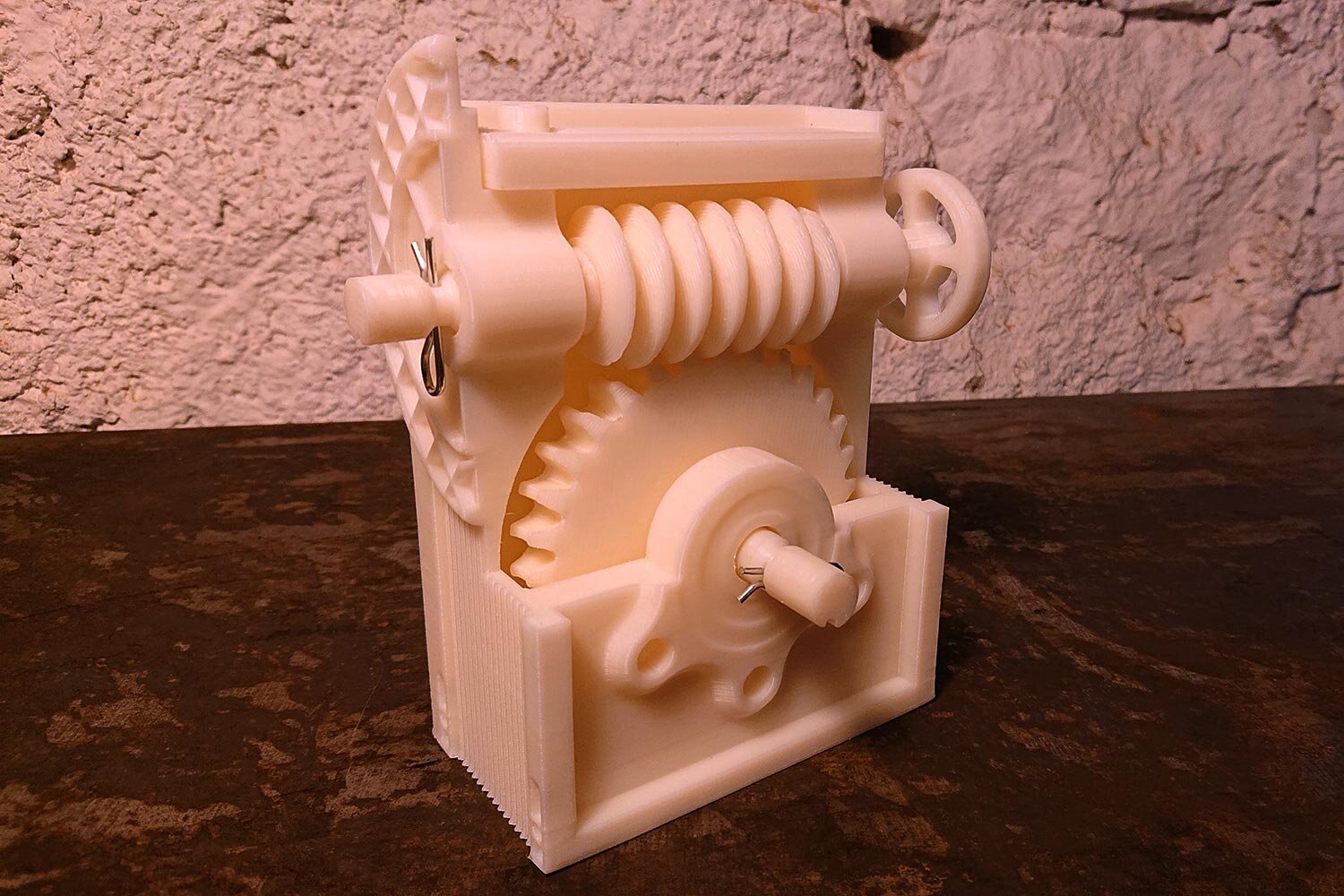

We also boast many valuable years working in pre-print optimisation and post-print processing. All of this production experience comes together before the printer starts extruding - meaning you save time and money from the beginning.

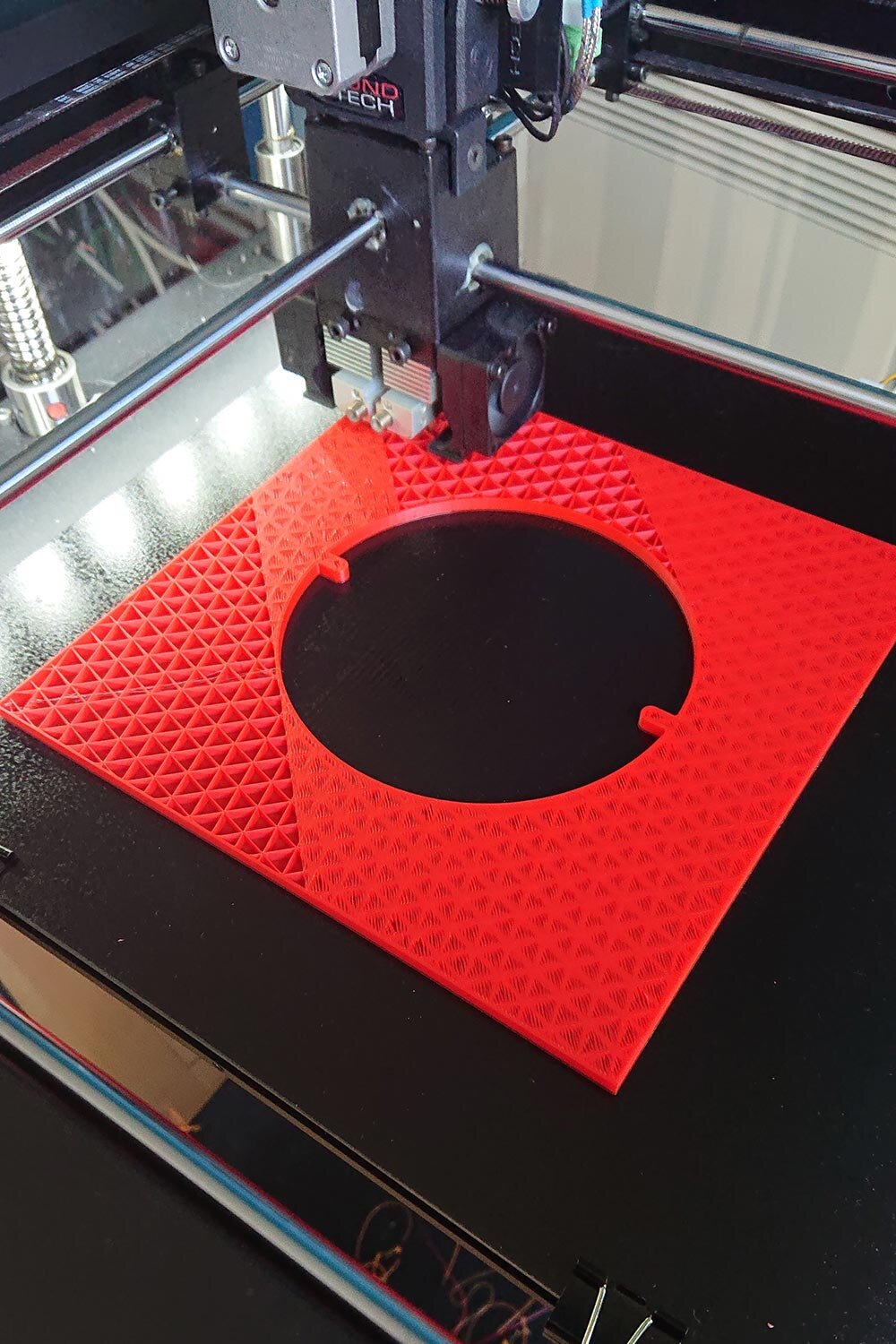

Equipment

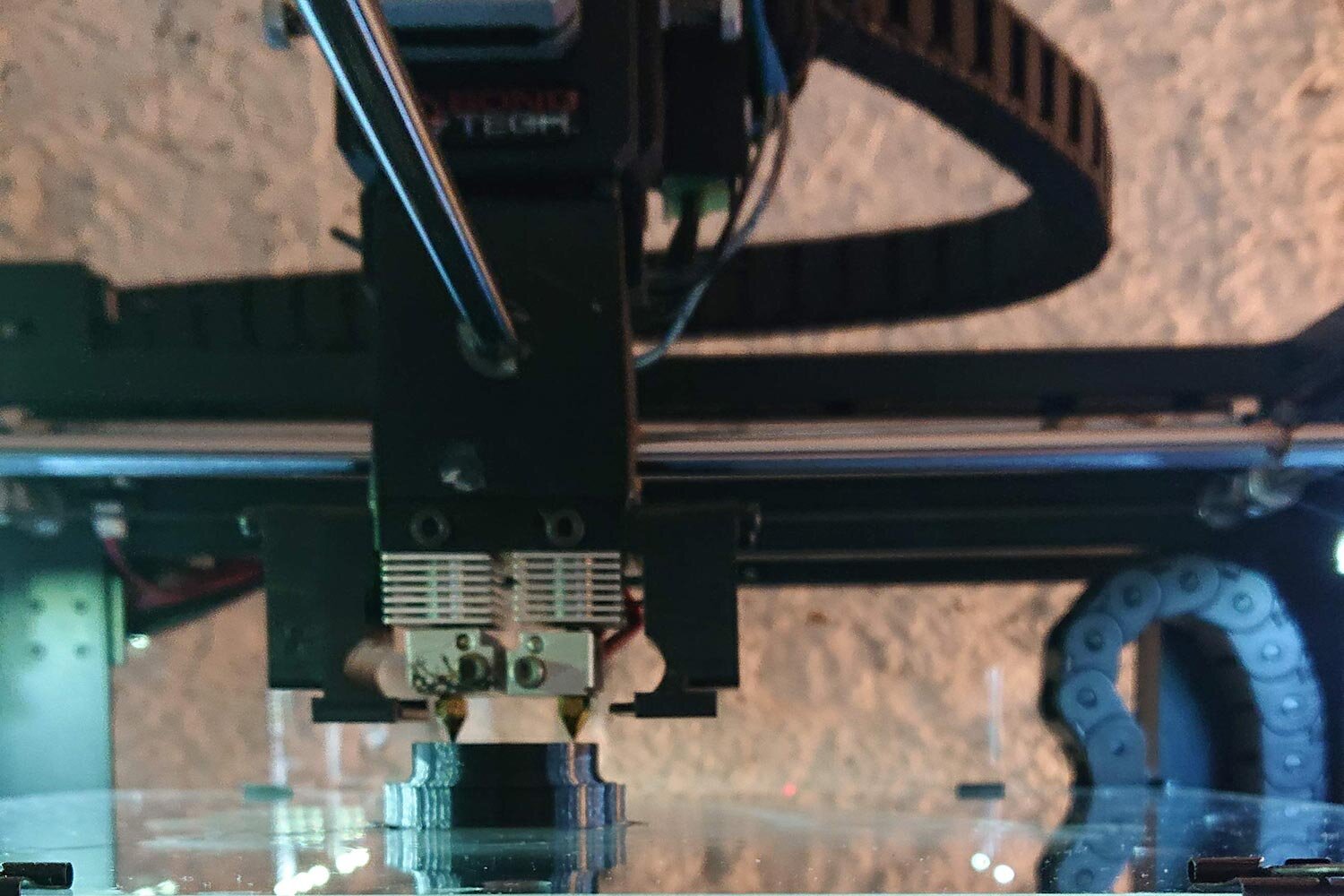

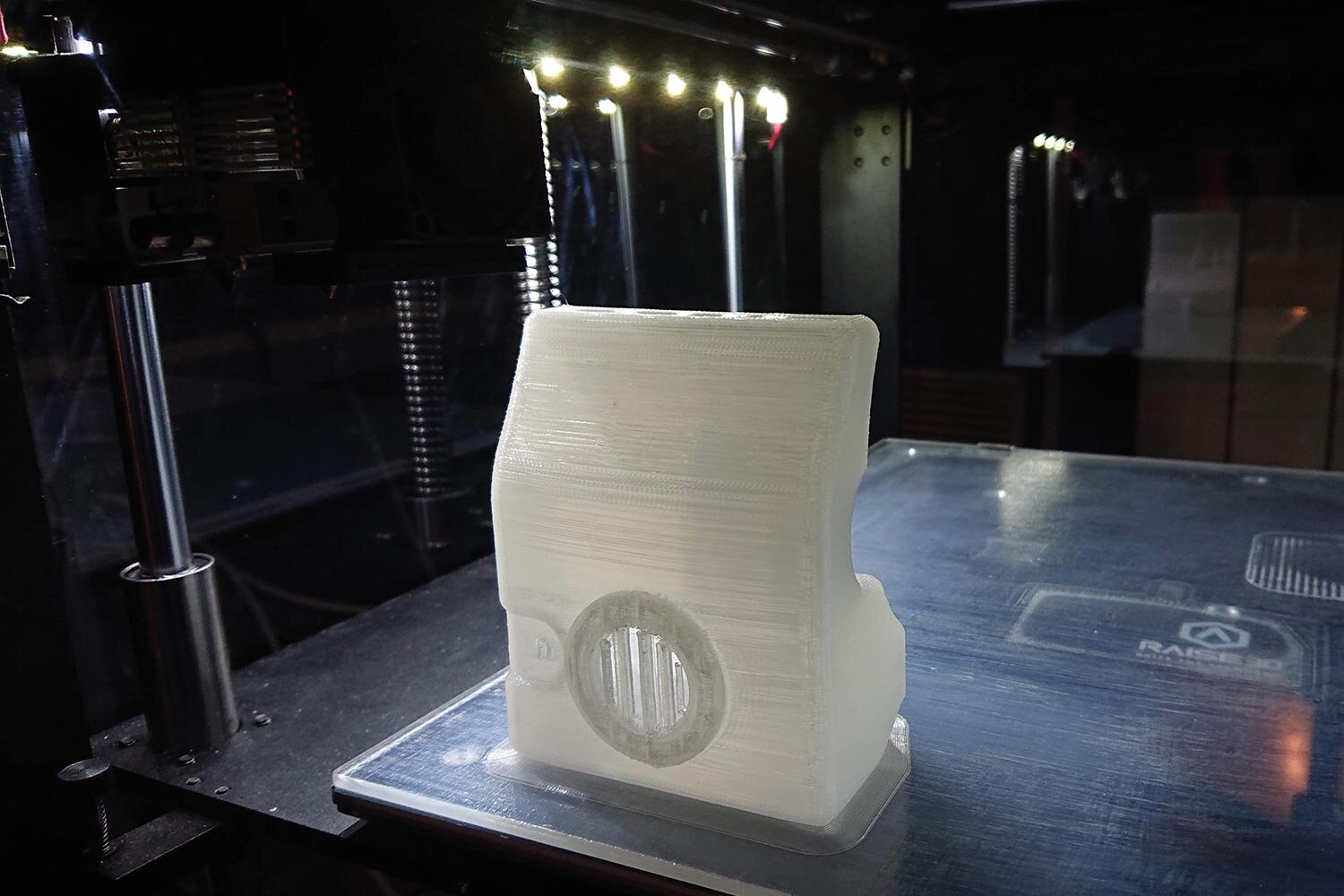

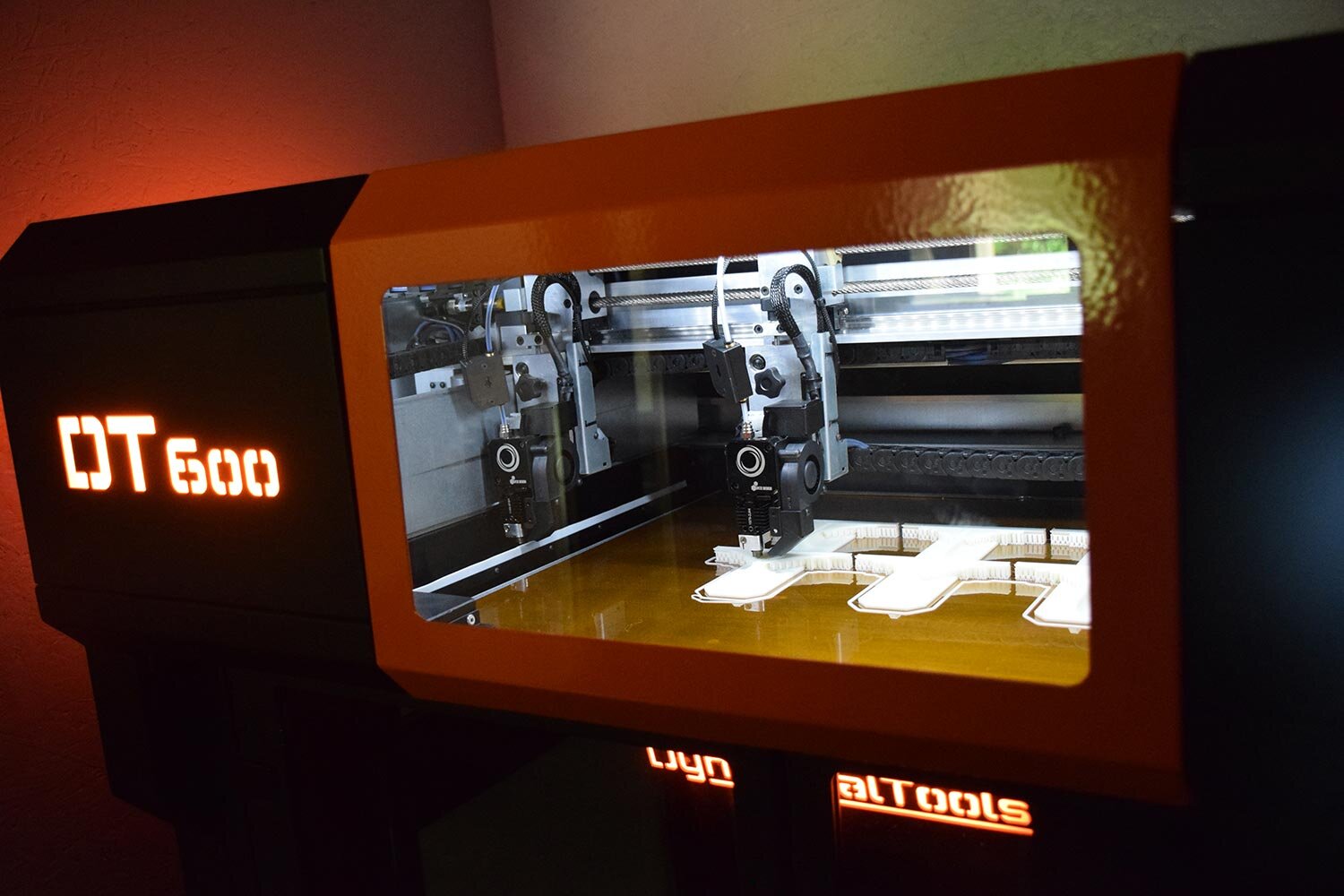

Our 3d printers are robust, industrial fused filament fabrication (FFF) machines. FFF printers offer the widest range of thermoplastic materials and capabilities.

With large print volumes, heated build chambers and high temperature capabilities, our industrial printers have been selected to process the most technical of engineering-grade materials.

“With 3d printing complexity is free. The printer doesn’t care if it makes the most rudimentary shape or the most complex shape. And that is completely turning design and manufacturing on its head as we know it.”